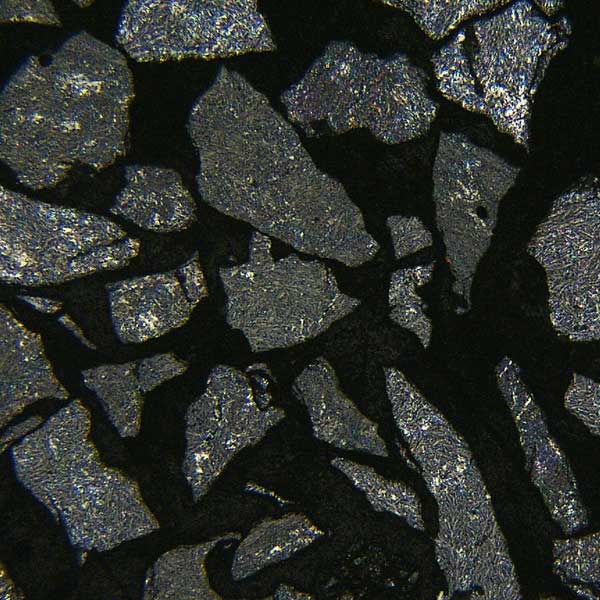

Cast wolframkarbidpoeder

Cast Tungsten Carbide (CTC) Poeder wurdt makke fan smelten en crushing W en WC en is unregelmjittige donkere grize dieltsjes mei in hege rimpelpunt (2525 ℃), hege hurdens (≥ 2000 HV0.1), en poerbêste wear ferset.

CTC wurdt brûkt foar it tarieden fan PDC matrix bits poeder, Plasma Arc Welding (PTAW) poeder, spray welding materialen, cemented carbid wear-resistant elektroden (wire), ensfh It primêre doel is om pre-fersterke wear-resistant oerflakken of reparearje droegen oerflakken foar mynbou, oalje en gas, metallurgy, boumasjines, lânboumasines, en stiel yndustry.

Gemyske gearstalling (Wt, %)

|

Klasse |

Gemyske gearstalling (Wt, %) |

|||||||

|

W |

T.C |

F.C |

Cr |

V |

Si |

O |

Fe |

|

|

ZTC11 |

95 – 96 |

3.8 – 4.1 |

≤ 0,08 |

≤ 0,01 |

≤ 0,05 |

≤ 0,02 |

≤ 0,05 |

≤ 0,3 |

OO

Grade en partikelgrutte

|

Klasse |

Par(cle Grutte (mesh)* |

Corresponsive Size Range (μm) |

|

ZTC1109 |

– 20 + 30 |

– 850 + 600 |

|

ZTC1111 |

– 30 + 40 |

– 600 + 425 |

|

ZTC1115 |

– 40 + 60 |

– 425 + 250 |

|

ZTC1119 |

– 60 + 80 |

– 250 + 180 |

|

ZTC1126 |

– 60 + 325 |

– 250 + 45 |

|

ZTC1127 |

– 70 + 400 |

– 212 + 38 |

|

ZTC1123 |

– 80 + 120 |

– 180 + 125 |

|

ZTC1149 |

– 80 + 170 |

– 180 + 90 |

|

ZTC1128 |

– 80 + 200 |

– 180 + 75 |

|

ZTC1129 |

– 100 + 140 |

– 150 + 106 |

|

ZTC1130 |

– 100 + 200 |

– 150 + 75 |

|

ZTC1131 |

– 100 + 230 |

– 150 + 63 |

|

ZTC1133 |

– 100 + 325 |

– 150 + 45 |

|

ZTC1134 |

– 120 + 170 |

– 125 + 90 |

|

ZTC1190 |

– 120 + 230 |

– 125 + 63 |

|

ZTC1140 |

– 140 + 200 |

– 106 + 75 |

|

ZTC1139 |

– 140 + 325 |

– 106 + 45 |

|

ZTC1142 |

– 170 + 325 |

– 90 + 45 |

|

ZTC1143 |

– 200 + 325 |

– 75 + 45 |

|

ZTC1147 |

– 325 |

– 45 |

|

ZTC1148 |

– 400 |

– 38 |

*: Wy kinne ferskillende par7cle maten op maat meitsje foar ferskate tapassingen.

Frysk

Frysk Ingelsk

Ingelsk Afrikaansk

Afrikaansk Albaneesk

Albaneesk Amhaarsk

Amhaarsk Arabysk

Arabysk Armeensk

Armeensk Baskysk

Baskysk Wytrussysk

Wytrussysk Bengaalsk

Bengaalsk Bosnysk

Bosnysk Bulgaarsk

Bulgaarsk Katalaansk

Katalaansk Cebuano

Cebuano Kroatysk

Kroatysk Tsjechysk

Tsjechysk Deensk

Deensk Nederlânsk

Nederlânsk Esperanto

Esperanto Estysk

Estysk Finsk

Finsk Frânsk

Frânsk Galyskysk

Galyskysk Georgysk

Georgysk Dútsk

Dútsk Gryksk

Gryksk Hebrieuwsk

Hebrieuwsk Hindoestaansk

Hindoestaansk Hongaarsk

Hongaarsk Yndonesysk

Yndonesysk Yslânsk

Yslânsk Italiaansk

Italiaansk Japansk

Japansk Javaansk

Javaansk Kannada

Kannada Kazachsk

Kazachsk Khmer

Khmer Koreaansk

Koreaansk Koerdysk

Koerdysk Kirgizysk

Kirgizysk Laotjaansk

Laotjaansk Letsk

Letsk Litousk

Litousk Masedoanysk

Masedoanysk Maleisk

Maleisk Malayalam

Malayalam Maratysk

Maratysk Mongoalsk

Mongoalsk Birma

Birma Nepaleesk

Nepaleesk Noarsk

Noarsk Oksitaansk

Oksitaansk Panjaby

Panjaby Pashtu

Pashtu Perzysk

Perzysk Poalsk

Poalsk Portegeesk

Portegeesk Roemeensk

Roemeensk Russysk

Russysk Skotsk Gaelic

Skotsk Gaelic Servysk

Servysk Sindysk

Sindysk Sinhala

Sinhala Slowaaksk

Slowaaksk Sloveensk

Sloveensk Spaansk (Meksiko)

Spaansk (Meksiko) Spaansk (Spanje)

Spaansk (Spanje) Swahily

Swahily Sweedsk

Sweedsk Tagaloch

Tagaloch Tamyl

Tamyl Tatar

Tatar Telugu

Telugu Taisk

Taisk Turksk

Turksk Uighur

Uighur Oekraynsk

Oekraynsk Uzbek

Uzbek Urdu

Urdu Fietnameesk

Fietnameesk Welsh

Welsh