Cr3C2-37WC-18NiCoCr Thermal Spray Poeder

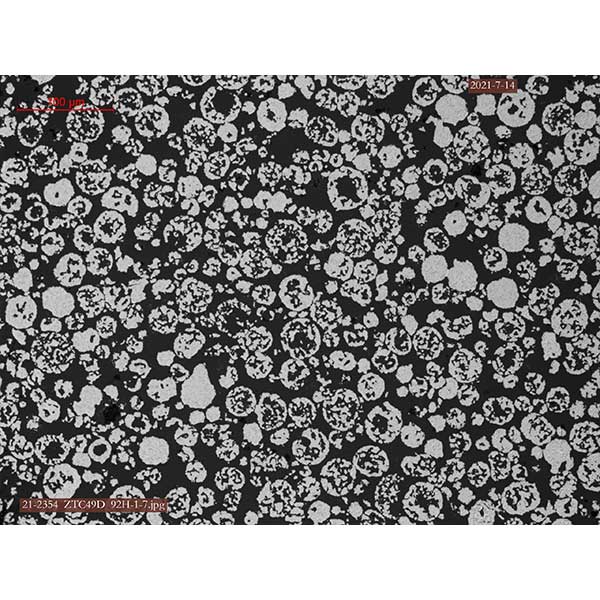

- Agglomerearre en Sintered griis-swarte sfearyske of near-sferyske dieltsjes.

- The maximum service temperature is up to 700℃.

- De coating hat poerbêste wjerstân tsjin sliding wear, abrasive wear, erosive wear, corrosive wear, cavitation, en corrosie.

- Excellent ferset tsjin fêste, floeibere en gas corrosie yn ferhege temperatueren.

- Excellent resistance to high-temperature complex corrosion.

Mainly used in pump valve parts, power generation boilers, biomass-burning boilers, the chemical

Grade & gemyske gearstalling

|

Klasse |

Gemyske gearstalling (Wt, %) |

||||||

|

W |

T.C |

Co |

Ni |

Cr |

O |

Fe |

|

|

ZTC49D* |

Lykwicht |

7.8 – 8.4 |

3 – 4 |

10.5 – 12.5 | 39.5 – 42.5 |

≤ 0,5 |

< 0.5 |

*: D stiet foar sferysk of near-sfearysk thermysk spuitpoeder.

Grutte & Fysike Eigenskippen

|

Klasse |

Type |

Grutte fraksje (μm) |

Skynbere tichtens (g/cm³) |

Flow Rate (s/50g) |

Oanfraach |

|

ZTC4951D |

Cr3C2 – WC – NiCoCr 45/37/18 Agglomerearre & Sinter |

– 53 + 20 |

≥ 2.5 |

— |

(JP5000 & JP8000, DJ2600 & DJ2700, JetKote, Woka Jet, K2)

|

|

ZTC4953D |

– 45 + 20 |

≥ 2.5 |

— |

||

|

ZTC4952D |

– 45 + 15 |

≥ 2.5 |

— |

||

|

ZTC4981D |

– 45 + 11 |

≥ 2.5 |

— |

||

|

ZTC4954D |

– 38 + 10 |

≥ 2.5 |

— |

||

|

ZTC4982D |

– 30 + 10 |

≥ 2.5 |

— |

||

| Wy kinne ferskillende partikelgrutte distribúsjes en skynbere tichtheden op maat meitsje foar ferskate tapassingen. | |||||

| Oanrikkemandearre spuitparameters (HVOF) |

|

Coating Eigenskippen |

||

| Materiaal |

Cr3C2 – 37WC – 18NiCoCr |

|

Hardheid (HV0.3) |

1050 – 1250 |

| Manufacturing |

Agglomerearre & Sintered |

|

Bonding Strength (MPa) |

> 60MPa |

| Grutte fraksje ( µm ) |

– 45 + 15 |

|

Deponearre effisjinsje (%) |

40 – 48% |

| Spray fakkel |

JP5000 |

|

Porositeit (%) |

< 3% |

| Nozzle (inch) |

6 |

|

|

|

| Kerosine (L/h) |

25 |

|

||

| Oxygen (l/min) |

900 |

|

||

| Dragergas (Ar) (L/min) |

7.5 |

|

||

| Poeder feed rate (g/min) |

70 – 80 |

|

||

| Spuitafstand (mm) |

320 – 380 |

|

||

Frysk

Frysk Ingelsk

Ingelsk Afrikaansk

Afrikaansk Albaneesk

Albaneesk Amhaarsk

Amhaarsk Arabysk

Arabysk Armeensk

Armeensk Baskysk

Baskysk Wytrussysk

Wytrussysk Bengaalsk

Bengaalsk Bosnysk

Bosnysk Bulgaarsk

Bulgaarsk Katalaansk

Katalaansk Cebuano

Cebuano Kroatysk

Kroatysk Tsjechysk

Tsjechysk Deensk

Deensk Nederlânsk

Nederlânsk Esperanto

Esperanto Estysk

Estysk Finsk

Finsk Frânsk

Frânsk Galyskysk

Galyskysk Georgysk

Georgysk Dútsk

Dútsk Gryksk

Gryksk Hebrieuwsk

Hebrieuwsk Hindoestaansk

Hindoestaansk Hongaarsk

Hongaarsk Yndonesysk

Yndonesysk Yslânsk

Yslânsk Italiaansk

Italiaansk Japansk

Japansk Javaansk

Javaansk Kannada

Kannada Kazachsk

Kazachsk Khmer

Khmer Koreaansk

Koreaansk Koerdysk

Koerdysk Kirgizysk

Kirgizysk Laotjaansk

Laotjaansk Letsk

Letsk Litousk

Litousk Masedoanysk

Masedoanysk Maleisk

Maleisk Malayalam

Malayalam Maratysk

Maratysk Mongoalsk

Mongoalsk Birma

Birma Nepaleesk

Nepaleesk Noarsk

Noarsk Oksitaansk

Oksitaansk Panjaby

Panjaby Pashtu

Pashtu Perzysk

Perzysk Poalsk

Poalsk Portegeesk

Portegeesk Roemeensk

Roemeensk Russysk

Russysk Skotsk Gaelic

Skotsk Gaelic Servysk

Servysk Sindysk

Sindysk Sinhala

Sinhala Slowaaksk

Slowaaksk Sloveensk

Sloveensk Spaansk (Meksiko)

Spaansk (Meksiko) Spaansk (Spanje)

Spaansk (Spanje) Swahily

Swahily Sweedsk

Sweedsk Tagaloch

Tagaloch Tamyl

Tamyl Tatar

Tatar Telugu

Telugu Taisk

Taisk Turksk

Turksk Uighur

Uighur Oekraynsk

Oekraynsk Uzbek

Uzbek Urdu

Urdu Fietnameesk

Fietnameesk Welsh

Welsh