WC-6Co Thermal Spray Powder

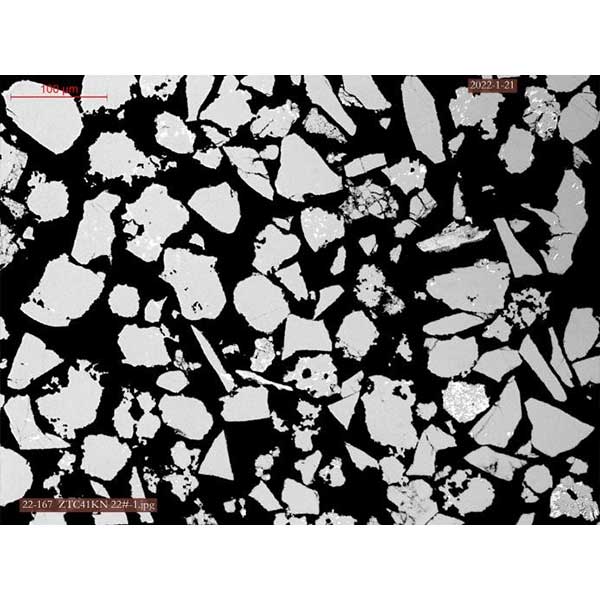

- Sintered and crushed powders are irregular.

- The maximum service temperature is up to 500℃.

- The dense coating has high hardness with excellent resistance to abrasive wear, fretting wear, adhesive wear, and erosion wear.

- High fracture toughness.

- Mainly used in mechanical parts, oil and gas equipment, metallurgical roller and pump seal, etc.

Grade & Chemical Composition

|

Grade |

Chemical Composition (Wt, %) |

||||

|

W |

T. C |

Co |

Fe |

O |

|

|

ZTC41 |

Balance |

5.2 – 6.0 |

5.5-6.5 |

≤ 1.0 |

≤ 0.5 |

Size & Physical Properties

|

Grade |

Type |

Size Fraction (μm) |

Apparent Density ( g/cm³) |

Flow Rate (s/50g) |

Application |

| ZTC41D3 |

WC – Co 94/6 Sintered & Crushed |

-53 |

≥ 4 |

≤ 25 |

(JP5000 & JP8000, DJ2600 & DJ2700, JetKote, Woka Jet, K2)

|

| ZTC4148 |

-38 |

≥ 4 |

≤ 25 |

||

| ZTC4130 |

-150+75 |

≥ 4 |

≤ 25 |

||

| ZTC4131 |

-150+63 |

≥ 4 |

≤ 18 |

||

| ZTC4139 |

-106+45 |

≥ 4 |

≤ 18 |

||

| ZTC4167 |

-106+53 |

≥ 4 |

≤ 18 |

||

| ZTC4152 |

-45+15 |

≥ 4 |

≤ 18 |

||

| ZTC4154 |

-38+10 |

≥ 4 |

≤ 25 |

||

| We can tailor-make different particle size distributions and apparent densities for various applications. | |||||

| Recommended Spray Parameters (HVOF) |

|

Coating Properties |

||

| Material |

WC – 10Co – 4Cr |

|

Hardness (HV0.3) |

1150 – 1400 |

| Manufacturing |

Agglomerated & Sintered |

|

Bonding Strength (MPa) |

> 70MPa |

| Size Fraction (µm) |

– 45 + 15 |

|

Deposited efficiency (%) |

40 – 55% |

| Spray Torch |

JP5000 |

|

Porosity (%) |

< 1% |

| Nozzle (inch) |

6 |

|

|

|

| Kerosene (L/h) |

24 |

|

||

| Oxygen (L/min) |

944 |

|

||

| Carrier gas (Ar) (L/min) |

7.5 |

|

||

| Powder feed rate (g/min) |

70 – 80 |

|

||

| Spraying distance (mm) |

340 – 380 |

|

||

English

English Afrikaans

Afrikaans Albanian

Albanian Amharic

Amharic Arabic

Arabic Armenian

Armenian Basque

Basque Belarusian

Belarusian Bengali

Bengali Bosnian

Bosnian Bulgarian

Bulgarian Catalan

Catalan Cebuano

Cebuano Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Esperanto

Esperanto Estonian

Estonian Finnish

Finnish French

French Frisian

Frisian Galician

Galician Georgian

Georgian German

German Greek

Greek Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Indonesian

Indonesian Icelandic

Icelandic Italian

Italian Japanese

Japanese Javanese

Javanese Kannada

Kannada Kazakh

Kazakh Khmer

Khmer Korean

Korean Kurdish

Kurdish Kyrgyz

Kyrgyz Lao

Lao Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Malayalam

Malayalam Marathi

Marathi Mongolian

Mongolian Myanmar

Myanmar Nepali

Nepali Norwegian

Norwegian Occitan

Occitan Panjabi

Panjabi Pashto

Pashto Persian

Persian Polish

Polish Portuguese

Portuguese Romanian

Romanian Russian

Russian Scottish Gaelic

Scottish Gaelic Serbian

Serbian Sindhi

Sindhi Sinhala

Sinhala Slovak

Slovak Slovenian

Slovenian Spanish (Mexico)

Spanish (Mexico) Spanish (Spain)

Spanish (Spain) Swahili

Swahili Swedish

Swedish Tagalog

Tagalog Tamil

Tamil Tatar

Tatar Telugu

Telugu Thai

Thai Turkish

Turkish Uighur

Uighur Ukrainian

Ukrainian Uzbek

Uzbek Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh