WC-10Co4Cr termal buzadigan amallar kukuni

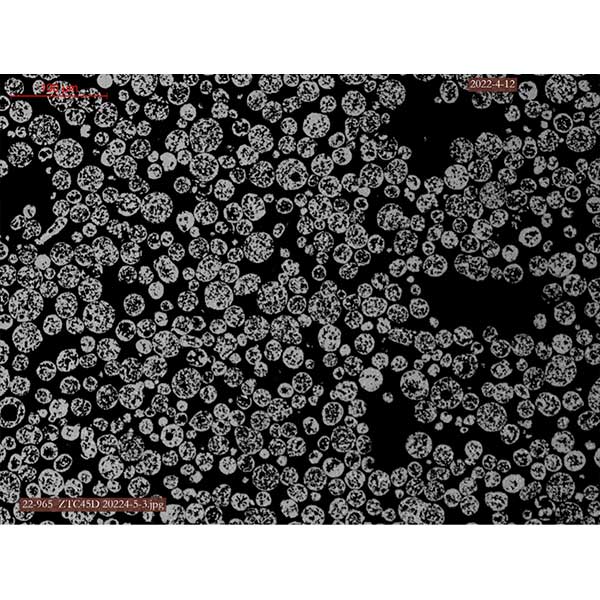

- Aglomeratsiyalangan va sinterlangan va sinterlangan va maydalangan kukun mavjud. Aglomeratsiyalangan va sinterlangan kukunlar sferik yoki sferikga yaqin bo'lib, yaxshi oqimga ega. Sinterlangan va maydalangan kukunlar tartibsizdir.

- Maksimal xizmat ko'rsatish harorati 500 ℃ gacha.

- Zich qoplama yuqori qattiqlikka ega bo'lib, abraziv aşınmaya, aşınmaya, yopishtiruvchi aşınmaya va eroziyaga mukammal qarshilik ko'rsatadi.

- Replacing hard chrome plating.

- Cobalt &Chrome has better corrosion resistance and wear properties than Cobalt, especially in wetting and corrosion environments.

- Mainly used in aircraft landing gear, gate valves, ball valves, paper rollers, hydraulic cylinders, compressor rods, metallurgical rollers, mechanical parts, etc.

Darajasi va kimyoviy tarkibi

|

Baho |

Kimyoviy tarkibi (Vt, %) |

|||||

|

V |

T. C |

Co |

Cr |

Fe |

O |

|

|

ZTC45 |

Balans |

5.2 – 6.0 |

9.1 – 10.1 |

3.0 – 4.5 |

≤ 1,0 |

≤ 0,5 |

|

ZTC45D* |

Balans |

5.2 – 6.0 |

9.1 – 10.1 |

3.0 – 4.5 |

≤ 0,15 |

≤ 0,5 |

*: D sferik yoki sferikga yaqin termal buzadigan amallar kukunini anglatadi.

Specification & Physical Properties

|

Baho |

Turi |

Hajmi kasr (mkm) |

Ko'rinadigan zichlik (g/sm³) |

Oqim darajasi (s/50 g) |

Ilova |

|

ZTC4551 |

WC – Co – Cr 86/10/4 Sintered & Crushed |

– 53 + 20 |

≥ 4 |

≤ 25 |

(JP5000 & JP8000, DJ2600 va DJ2700, JetKote, Woka Jet, K2)

|

|

ZTC4553 |

– 45 + 20 |

≥ 4 |

≤ 25 |

||

|

ZTC4552 |

– 45 + 15 |

≥4 |

≤ 25 |

||

|

ZTC4551D |

WC – Co – Cr 86/10/4 Aglomeratsiyalangan & Sinterlangan |

– 53 + 20 |

≥ 4 |

≤ 18 |

|

|

ZTC4553D |

– 45 + 20 |

≥ 4 |

≤18 |

||

|

ZTC4552D |

– 45 + 15 |

≥ 4 |

≤18 |

||

|

ZTC4581D |

– 45 + 11 |

≥ 4 |

≤18 |

||

|

ZTC4554D |

– 38 + 10 |

≥ 4 |

≤18 |

||

|

ZTC4582D |

– 30 + 10 |

≥ 4 |

≤ 18 |

||

| Biz turli xil ilovalar uchun zarracha o'lchamlari va ko'rinadigan zichliklarni moslashtira olamiz. | |||||

| Tavsiya etilgan purkash parametrlari (HVOF) |

|

Qoplash xususiyatlari |

||

| Material |

WC – 10Co – 4Cr |

|

Qattiqlik (HV0.3) |

1150 – 1400 |

| Ishlab chiqarish |

Aglomeratsiyalangan va sinterlangan |

|

Bog'lanish kuchi (MPa) |

> 70MPa |

| Hajmi ulushi ( µm ) |

– 45 + 15 |

|

Depozit qilingan samaradorlik (%) |

40 – 55% |

| Spray mash'alasi |

JP5000 |

|

Porozlik (%) |

< 1% |

| Ko‘krak (dyuym) |

6 |

|

|

|

| Kerosin (L/soat) |

24 |

|

||

| Kislorod (L/min) |

944 |

|

||

| Tashuvchi gaz (Ar) (L/min) |

7.5 |

|

||

| Kukunning oziqlanish tezligi (g/min) |

70 – 80 |

|

||

| Püskürtme masofasi (mm) |

340 – 380 |

|

||

o'zbek

o'zbek Ingliz

Ingliz afrikaans

afrikaans alban

alban Amhar

Amhar arabcha

arabcha arman

arman bask

bask belarus

belarus bengal

bengal bosniyalik

bosniyalik bolgar

bolgar katalan

katalan Sebuano

Sebuano xorvat

xorvat chex

chex Daniya

Daniya golland

golland Esperanto

Esperanto eston

eston fin

fin frantsuz

frantsuz frizcha

frizcha Galisian

Galisian gruzin

gruzin nemis

nemis yunoncha

yunoncha ibroniy

ibroniy hind

hind venger

venger indonez

indonez island

island italyancha

italyancha yapon

yapon yava

yava Kannada

Kannada qozoq

qozoq kxmer

kxmer koreys

koreys kurd

kurd qirg'iz

qirg'iz Lao

Lao latviyalik

latviyalik litva

litva makedon

makedon malay

malay Malayalam

Malayalam marati

marati mo'g'ul

mo'g'ul Myanma

Myanma Nepal

Nepal norveg

norveg oksitan

oksitan panjabi

panjabi Pushtu

Pushtu forscha

forscha polyak

polyak portugal

portugal rumin

rumin rus

rus Shotlandiya gael tili

Shotlandiya gael tili serb

serb Sindhi

Sindhi Sinhala

Sinhala slovak

slovak sloven

sloven Ispan (Meksika)

Ispan (Meksika) Ispan (Ispaniya)

Ispan (Ispaniya) suahili

suahili shved

shved Tagalog

Tagalog Tamil

Tamil tatar

tatar Telugu

Telugu tay

tay turkcha

turkcha uyg'ur

uyg'ur ukrain

ukrain urdu

urdu Vetnam

Vetnam uels

uels