WC-12Co Thermal Spray Powder

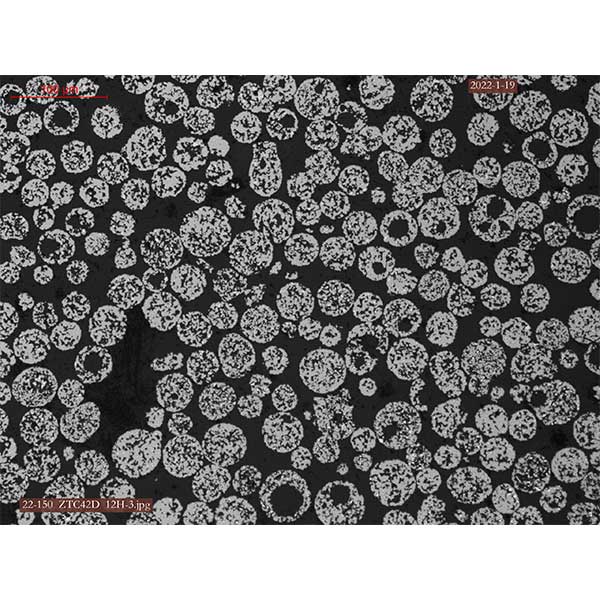

- Parehong available ang Agglomerated & Sintered at Sintered at Crushed powder. Ang mga agglomerated at sintered na pulbos ay spherical o malapit sa spherical na may mahusay na flowability. Ang mga sintered at durog na pulbos ay hindi regular.

- Ang pinakamataas na temperatura ng serbisyo ay hanggang 500 ℃.

- Ang siksik na patong ay may mataas na tigas na may mahusay na pagtutol sa abrasive wear, fretting wear, adhesive wear, at erosion wear.

- Mataas na tibay ng bali.

- Pangunahing ginagamit sa mga mekanikal na bahagi, kagamitan sa langis at gas, metalurhiko roller at pump seal, atbp.

Marka at Komposisyon ng Kemikal

|

Grade |

Komposisyon ng Kemikal (Wt, %) |

||||

|

W |

T. C |

Co |

Fe |

O |

|

|

ZTC42 |

Balanse |

5.2 – 6.0 |

11.5 – 12.5 |

≤ 1.0 |

≤ 0.5 |

|

ZTC42D* |

Balanse |

5.2 – 6.0 |

11.5 – 12.5 |

≤ 0.15 |

≤ 0.5 |

*: D ay nangangahulugang spherical o near-spherical thermal spray powder.

S ize at Pisikal na Katangian

|

Grade |

Uri |

Sukat Fraction (μm) |

Malinaw na Densidad ( g/cm³) |

Daloy ng rate (s/50g) |

Aplikasyon |

|

ZTC4251 |

WC – Co 88/12 Sintered at Durog |

– 53 + 20 |

≥ 4 |

≤ 25 |

(JP5000 at JP8000, DJ2600 at DJ2700, JetKote, Woka Jet, K2)

|

|

ZTC4253 |

– 45 + 20 |

≥ 4 |

≤ 25 |

||

|

ZTC4252 |

– 45 + 15 |

≥ 4 |

≤ 25 |

||

|

ZTC4251D |

WC – Co 88/12 Pinagsama-sama & Sintered |

– 53 + 20 |

≥ 4 |

≤ 18 |

|

|

ZTC4253D |

– 45 + 20 |

≥ 4 |

≤ 18 |

||

|

ZTC4252D |

– 45 + 15 |

≥ 4 |

≤ 18 |

||

|

ZTC4281D |

– 45 + 11 |

≥ 4 |

≤ 18 |

||

|

ZTC4254D |

– 38 + 10 |

≥ 4 |

≤ 18 |

||

|

ZTC4282D |

– 30 + 10 |

≥ 4 |

≤ 18 |

||

| Maaari naming iangkop ang iba't ibang mga pamamahagi ng laki ng butil at maliwanag na densidad para sa iba't ibang aplikasyon. | |||||

| Mga Inirerekomendang Spray Parameter (HVOF) |

|

Mga Katangian ng Patong |

||

| materyal |

WC – 12Co |

|

Katigasan (HV0.3) |

1100 – 1300 |

| Paggawa |

Pinagsama-sama at Sintered |

|

Lakas ng Pagbubuklod (MPa) |

> 70MPa |

| Laki ng Fraction ( µ m) |

– 45 + 15 |

|

Na-deposito na kahusayan (%) |

40 – 50% |

| Pag-spray ng Torch |

JP5000 |

|

Porosity (%) |

< 1% |

| nozzle (pulgada) |

6 |

|

|

|

| Kerosene (L/h) |

22.7 |

|

||

| Oxygen (L/min) |

944 |

|

||

| Carrier gas (Ar) (L/min) |

7.5 |

|

||

| Rate ng pagpapakain ng pulbos (g/min) |

70 – 100 |

|

||

| Distansya ng pag-spray (mm) |

350 – 380 |

|

||

Tagalog

Tagalog Ingles

Ingles Afrikaans

Afrikaans Albaniano

Albaniano Amharic

Amharic Arabic

Arabic Armenian

Armenian Basque

Basque Belarusian

Belarusian Bengali

Bengali Bosnian

Bosnian Bulgarian

Bulgarian Catalan

Catalan Cebuano

Cebuano Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Esperanto

Esperanto Estonian

Estonian Finnish

Finnish Pranses

Pranses Frisian

Frisian Galician

Galician Georgian

Georgian Aleman

Aleman Griyego

Griyego Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Indonesian

Indonesian Icelandic

Icelandic Italyano

Italyano Hapon

Hapon Javanese

Javanese Kannada

Kannada Kazakh

Kazakh Khmer

Khmer Koreano

Koreano Kurdish

Kurdish Kyrgyz

Kyrgyz Lao

Lao Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Malayalam

Malayalam Marathi

Marathi Mongolian

Mongolian Myanmar

Myanmar Nepali

Nepali Norwegian

Norwegian Occitan

Occitan Panjabi

Panjabi Pashto

Pashto Persian

Persian Polish

Polish Portuges

Portuges Romanian

Romanian Ruso

Ruso Scottish Gaelic

Scottish Gaelic Serbian

Serbian Sindhi

Sindhi Sinhala

Sinhala Slovak

Slovak Slovenian

Slovenian Espanyol (Mexico)

Espanyol (Mexico) Espanyol (Espanya)

Espanyol (Espanya) Swahili

Swahili Swedish

Swedish Tamil

Tamil Tatar

Tatar Telugu

Telugu Thai

Thai Turkish

Turkish Uighur

Uighur Ukrainian

Ukrainian Uzbek

Uzbek Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh