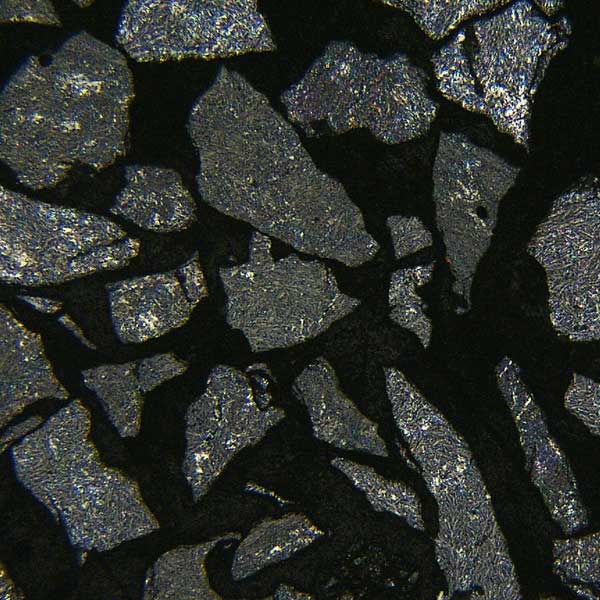

Cast Tungsten Carbide Powder

Ang Cast Tungsten Carbide (CTC) Powder ay gawa sa pagtunaw at pagdurog sa W at WC at ito ay hindi regular na dark gray na particle na may mataas na melting point (2525℃), mataas na tigas (≥ 2000 HV0.1), at mahusay na wear resistance.

Ginagamit ang CTC para maghanda ng PDC matrix bits powder, Plasma Arc Welding (PTAW) powder, spray welding materials, cemented carbide wear-resistant electrodes (wire), atbp. Ang pangunahing layunin ay paunang palakasin ang wear-resistant surface o ayusin ang mga sira na ibabaw. para sa pagmimina, langis at gas, metalurhiya, makinarya sa konstruksyon, makinarya sa agrikultura, at industriya ng bakal.

Komposisyon ng Kemikal (Wt, %)

|

Grade |

Komposisyon ng Kemikal (Wt, %) |

|||||||

|

W |

T. C |

F. C |

Cr |

V |

Si |

O |

Fe |

|

|

ZTC11 |

95 – 96 |

3.8 – 4.1 |

≤ 0.08 |

≤ 0.01 |

≤ 0.05 |

≤ 0.02 |

≤ 0.05 |

≤ 0.3 |

OO

Grado at Laki ng Particle

|

Grade |

Par(Cle Size (mesh)* |

Saklaw ng Sukat na Sukat (μm) |

|

ZTC1109 |

– 20 + 30 |

– 850 + 600 |

|

ZTC1111 |

– 30 + 40 |

– 600 + 425 |

|

ZTC1115 |

– 40 + 60 |

– 425 + 250 |

|

ZTC1119 |

– 60 + 80 |

– 250 + 180 |

|

ZTC1126 |

– 60 + 325 |

– 250 + 45 |

|

ZTC1127 |

– 70 + 400 |

– 212 + 38 |

|

ZTC1123 |

– 80 + 120 |

– 180 + 125 |

|

ZTC1149 |

– 80 + 170 |

– 180 + 90 |

|

ZTC1128 |

– 80 + 200 |

– 180 + 75 |

|

ZTC1129 |

– 100 + 140 |

– 150 + 106 |

|

ZTC1130 |

– 100 + 200 |

– 150 + 75 |

|

ZTC1131 |

– 100 + 230 |

– 150 + 63 |

|

ZTC1133 |

– 100 + 325 |

– 150 + 45 |

|

ZTC1134 |

– 120 + 170 |

– 125 + 90 |

|

ZTC1190 |

– 120 + 230 |

– 125 + 63 |

|

ZTC1140 |

– 140 + 200 |

– 106 + 75 |

|

ZTC1139 |

– 140 + 325 |

– 106 + 45 |

|

ZTC1142 |

– 170 + 325 |

– 90 + 45 |

|

ZTC1143 |

– 200 + 325 |

– 75 + 45 |

|

ZTC1147 |

– 325 |

– 45 |

|

ZTC1148 |

– 400 |

– 38 |

*: Maaari naming iangkop ang iba't ibang laki ng par7cle para sa iba't ibang aplikasyon.

Tagalog

Tagalog Ingles

Ingles Afrikaans

Afrikaans Albaniano

Albaniano Amharic

Amharic Arabic

Arabic Armenian

Armenian Basque

Basque Belarusian

Belarusian Bengali

Bengali Bosnian

Bosnian Bulgarian

Bulgarian Catalan

Catalan Cebuano

Cebuano Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Esperanto

Esperanto Estonian

Estonian Finnish

Finnish Pranses

Pranses Frisian

Frisian Galician

Galician Georgian

Georgian Aleman

Aleman Griyego

Griyego Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Indonesian

Indonesian Icelandic

Icelandic Italyano

Italyano Hapon

Hapon Javanese

Javanese Kannada

Kannada Kazakh

Kazakh Khmer

Khmer Koreano

Koreano Kurdish

Kurdish Kyrgyz

Kyrgyz Lao

Lao Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Malayalam

Malayalam Marathi

Marathi Mongolian

Mongolian Myanmar

Myanmar Nepali

Nepali Norwegian

Norwegian Occitan

Occitan Panjabi

Panjabi Pashto

Pashto Persian

Persian Polish

Polish Portuges

Portuges Romanian

Romanian Ruso

Ruso Scottish Gaelic

Scottish Gaelic Serbian

Serbian Sindhi

Sindhi Sinhala

Sinhala Slovak

Slovak Slovenian

Slovenian Espanyol (Mexico)

Espanyol (Mexico) Espanyol (Espanya)

Espanyol (Espanya) Swahili

Swahili Swedish

Swedish Tamil

Tamil Tatar

Tatar Telugu

Telugu Thai

Thai Turkish

Turkish Uighur

Uighur Ukrainian

Ukrainian Uzbek

Uzbek Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh