WC-15NiCr Thermal Spray Poda

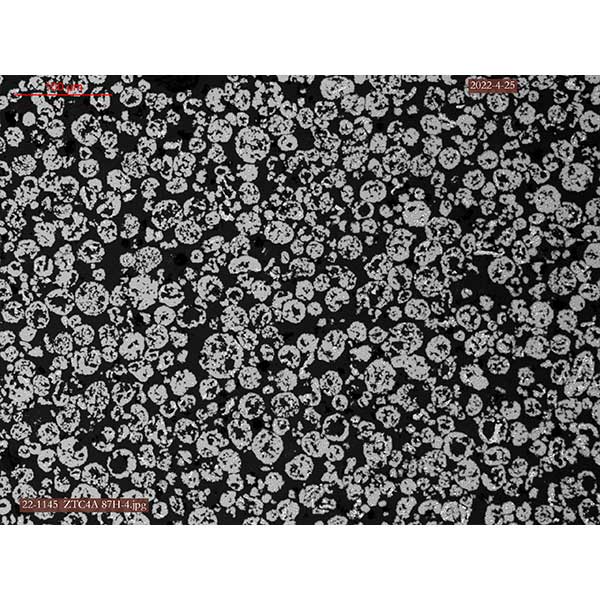

- Agglomerated na Sintered kijivu-nyeusi chembe duara au karibu-spherical na mtiririko mzuri.

- Kiwango cha juu cha joto cha huduma ni hadi 500 ℃.

- The density coating has high hardness with excellent resistance to abrasive wear, sliding wear, erosion wear, and cavitation.

- NiCr has better corrosion resistance than Cobalt, CoCr, and excellent resistance to seawater (Saltwater) corrosion.

- Mainly used in oil field equipment, ball valves (oxidizing environment), hydraulic gate levers, transportation container hydraulic levers, the petrochemical industry, offshore equipment, parts, etc.

Daraja & Muundo wa Kemikali

|

Daraja |

Muundo wa Kemikali (Wt, %) |

|||||

|

W |

T.C |

Cr |

Ni |

Fe |

O |

|

|

ZTC4CD* |

Mizani |

5.0 – 5.4 |

2.5 – 3.5 |

11.5 – 12.5 |

≤ 0.5 |

≤ 0.5 |

*: D inawakilisha poda ya kupuliza ya joto ya duara au karibu-spherical.

S ize & Sifa za Kimwili

|

Daraja |

Aina |

Sehemu ya Ukubwa (μm) |

Uzito Unaoonekana ( g/cm³) |

Kiwango cha Mtiririko (s/50g) |

Maombi |

|

ZTC4C51D |

WC – Ni – Cr

85/12/3 Imechangiwa & Sintered |

– 53 + 20 |

≥ 4 |

≤ 18 |

(JP5000 & JP8000, DJ2600 & DJ2700, JetKote, Woka Jet, K2)

|

|

ZTC4C53D |

– 45 + 20 |

≥ 4 |

≤ 18 |

||

|

ZTC4C52D |

– 45 + 15 |

≥ 4 |

≤ 18 |

||

|

ZTC4C81D |

– 45 + 11 |

≥ 4 |

≤ 18 |

||

|

ZTC4C54D |

– 38 + 10 |

≥ 4 |

≤ 18 |

||

|

ZTC4C82D |

– 30 + 10 |

≥ 4 |

≤ 30 |

||

| Tunaweza kutengeneza ugawaji tofauti wa saizi ya chembe na msongamano dhahiri kwa matumizi anuwai. | |||||

| Vigezo vya Kunyunyuzia Vilivyopendekezwa (HVOF) |

|

Mali ya mipako |

||

| Nyenzo |

WC – 15NiCr |

|

Ugumu (HV0.3) |

1000 – 1350 |

| Utengenezaji |

Agglomerated & Sintered |

|

Nguvu ya Kuunganisha (MPa) |

> 70MPa |

| Sehemu ya Ukubwa ( µ m) |

– 45 + 15 |

|

Ufanisi uliowekwa (%) |

35 – 50% |

| Nyunyizia Mwenge |

JP5000 |

|

Porosity (%) |

< 1% |

| Pua (inchi) |

6 |

|

|

|

| Mafuta ya taa (L/h) |

23 |

|

||

| Oksijeni (L/dakika) |

900 |

|

||

| Gesi ya kibebea (Ar) (L/dakika) |

8.5 |

|

||

| Kiwango cha malisho ya unga (g/min) |

70 – 80 |

|

||

| Umbali wa kunyunyizia dawa (mm) |

340 – 380 |

|

||

kiswahili

kiswahili Kiingereza

Kiingereza Kiafrikana

Kiafrikana Kialbeni

Kialbeni Kiamhari

Kiamhari Kiarabu

Kiarabu Kiarmenia

Kiarmenia Kibasque

Kibasque Kibelarusi

Kibelarusi Kibengali

Kibengali Kibosnia

Kibosnia Kibulgaria

Kibulgaria Kikatalani

Kikatalani Cebuano

Cebuano Kikroeshia

Kikroeshia Kicheki

Kicheki Kideni

Kideni Kiholanzi

Kiholanzi Kiesperanto

Kiesperanto Kiestonia

Kiestonia Kifini

Kifini Kifaransa

Kifaransa Kifrisia

Kifrisia Kigalisia

Kigalisia Kijojiajia

Kijojiajia Kijerumani

Kijerumani Kigiriki

Kigiriki Kiebrania

Kiebrania Kihindi

Kihindi Kihungaria

Kihungaria Kiindonesia

Kiindonesia Kiaislandi

Kiaislandi Kiitaliano

Kiitaliano Kijapani

Kijapani Kijava

Kijava Kikanada

Kikanada Kazakh

Kazakh Khmer

Khmer Kikorea

Kikorea Kikurdi

Kikurdi Kirigizi

Kirigizi Lao

Lao Kilatvia

Kilatvia Kilithuania

Kilithuania Kimasedonia

Kimasedonia Kimalei

Kimalei Kimalayalam

Kimalayalam Marathi

Marathi Kimongolia

Kimongolia Myanmar

Myanmar Kinepali

Kinepali Kinorwe

Kinorwe Oksitani

Oksitani Panjabi

Panjabi Kipashto

Kipashto Kiajemi

Kiajemi Kipolandi

Kipolandi Kireno

Kireno Kiromania

Kiromania Kirusi

Kirusi Kigaeli cha Kiskoti

Kigaeli cha Kiskoti Kiserbia

Kiserbia Kisindhi

Kisindhi Kisinhala

Kisinhala Kislovakia

Kislovakia Kislovenia

Kislovenia Kihispania (Meksiko)

Kihispania (Meksiko) Kihispania (Uhispania)

Kihispania (Uhispania) Kiswidi

Kiswidi Kitagalogi

Kitagalogi Kitamil

Kitamil Kitatari

Kitatari Kitelugu

Kitelugu Thai

Thai Kituruki

Kituruki Uighur

Uighur Kiukreni

Kiukreni Kiuzbeki

Kiuzbeki Kiurdu

Kiurdu Kivietinamu

Kivietinamu Kiwelisi

Kiwelisi