Cr3C2-37WC-18NiCoCr Thermal Spray Powder

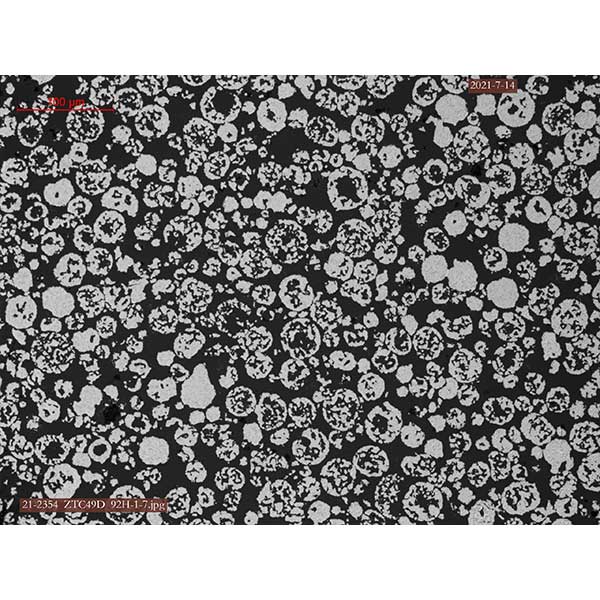

- Agglomerated lan Sintered abu-abu-ireng partikel bunder utawa cedhak-bunder.

- The maximum service temperature is up to 700℃.

- Lapisan kasebut nduweni resistensi banget kanggo nyandhang geser, nyandhang abrasif, nyandhang erosif, nyandhang korosif, cavitation, lan karat.

- Resistance banget kanggo korosi padhet, cair, lan gas ing suhu sing dhuwur.

- Excellent resistance to high-temperature complex corrosion.

Mainly used in pump valve parts, power generation boilers, biomass-burning boilers, the chemical

Komposisi Kelas & Kimia

|

kelas |

Komposisi Kimia (Wt, %) |

||||||

|

W |

T. C |

Co |

Ni |

Cr |

O |

Fe |

|

|

ZTC49D* |

imbangan |

7.8 – 8.4 |

3 – 4 |

10.5 – 12.5 | 39.5 – 42.5 |

≤ 0,5 |

< 0.5 |

*: D singkatan saka bubuk semprotan termal bunder utawa cedhak-bunder.

Size & Sifat Fisik

|

kelas |

Jinis |

Ukuran Fraksi (μm) |

Kapadhetan sing katon (g/cm³) |

Laju alur (s/50g) |

Aplikasi |

|

ZTC4951D |

Cr3C2 – WC – NiCoCr 45/37/18 Agglomerated & Sintered |

– 53 + 20 |

≥ 2.5 |

— |

(JP5000 & JP8000, DJ2600 & DJ2700, JetKote, Woka Jet, K2)

|

|

ZTC4953D |

– 45 + 20 |

≥ 2.5 |

— |

||

|

ZTC4952D |

– 45 + 15 |

≥ 2.5 |

— |

||

|

ZTC4981D |

– 45 + 11 |

≥ 2.5 |

— |

||

|

ZTC4954D |

– 38 + 10 |

≥ 2.5 |

— |

||

|

ZTC4982D |

– 30 + 10 |

≥ 2.5 |

— |

||

| Kita bisa nggawe macem-macem distribusi ukuran partikel lan kapadhetan sing katon kanggo macem-macem aplikasi. | |||||

| Parameter Semprotan sing Disaranake (HVOF) |

|

Properties Coating |

||

| Bahan |

Cr3C2 – 37WC – 18NiCoCr |

|

Kekerasan (HV0.3) |

1050 – 1250 |

| Manufaktur |

Agglomerated & Sintered |

|

Kekuatan Ikatan (MPa) |

> 60MPa |

| Ukuran Fraksi ( µm ) |

– 45 + 15 |

|

Efisiensi simpenan (%) |

40 – 48% |

| Semprotan Obor |

JP5000 |

|

Porositas (%) |

< 3% |

| Nozzle (inci) |

6 |

|

|

|

| Minyak tanah (L/h) |

25 |

|

||

| Oksigen (L/min) |

900 |

|

||

| Gas pembawa (Ar) (L/min) |

7.5 |

|

||

| Tingkat feed bubuk (g / mnt) |

70 – 80 |

|

||

| Jarak penyemprotan (mm) |

320 – 380 |

|

||

basa jawa

basa jawa Inggris

Inggris wong Afrikaans

wong Afrikaans basa Albania

basa Albania Amharic

Amharic Arab

Arab wong Armenia

wong Armenia Basque

Basque Belarusia

Belarusia Bengali

Bengali Bosnia

Bosnia basa Bulgaria

basa Bulgaria Katalan

Katalan Cebuano

Cebuano basa Kroasia

basa Kroasia Ceko

Ceko Danish

Danish Walanda

Walanda Esperanto

Esperanto basa Estonia

basa Estonia basa Finlandia

basa Finlandia Prancis

Prancis Frisian

Frisian Galician

Galician Georgian

Georgian Jerman

Jerman Yunani

Yunani basa Ibrani

basa Ibrani Hindi

Hindi Hungaria

Hungaria basa Indonesia

basa Indonesia basa Islandia

basa Islandia basa Italia

basa Italia Jepang

Jepang Kannada

Kannada Kazakh

Kazakh Khmer

Khmer Korea

Korea basa Kurdi

basa Kurdi Kyrgyz

Kyrgyz Lao

Lao Latvia

Latvia Lithuania

Lithuania Makedonia

Makedonia Melayu

Melayu Malayalam

Malayalam Marathi

Marathi Mongolian

Mongolian Myanmar

Myanmar Nepali

Nepali basa Norwegia

basa Norwegia Occitan

Occitan Panjabi

Panjabi Pashto

Pashto Persia

Persia Polandia

Polandia Portugis

Portugis basa Rumania

basa Rumania Rusian

Rusian Gaelik Skotlandia

Gaelik Skotlandia basa Serbia

basa Serbia Sindhi

Sindhi Sinhala

Sinhala basa Slowakia

basa Slowakia basa Slovenia

basa Slovenia Spanyol (Meksiko)

Spanyol (Meksiko) Spanyol (Spanyol)

Spanyol (Spanyol) Swahili

Swahili Swedia

Swedia Tagalog

Tagalog Tamil

Tamil Tatar

Tatar Telugu

Telugu Thai

Thai basa Turki

basa Turki Uighur

Uighur Ukrainia

Ukrainia Uzbek

Uzbek Basa Urdu

Basa Urdu Vietnam

Vietnam Welsh

Welsh