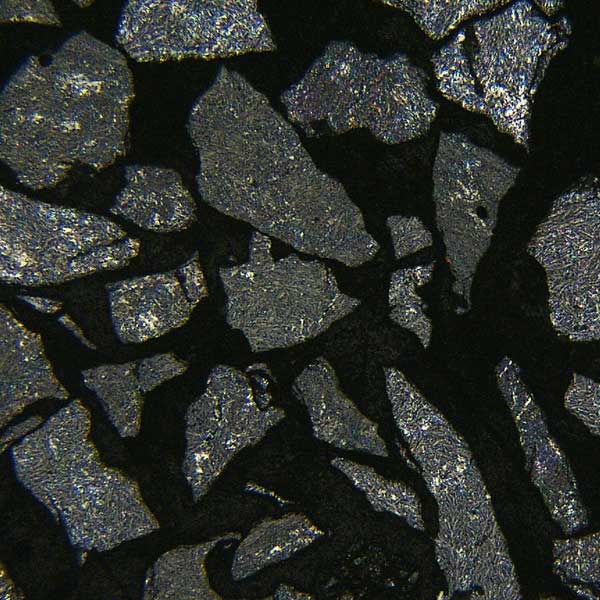

Cast Tungsten Carbide Powder

Cast Tungsten Carbide (CTC) Powder is made of melting and crushing W and WC and is irregular dark gray particles with a high melting point (2525℃), high hardness (≥ 2000 HV0.1), and excellent wear resistance.

CTC is used to prepare PDC matrix bits powder, Plasma Arc Welding (PTAW) powder, spray welding materials, cemented carbide wear-resistant electrodes (wire), etc. The primary purpose is to pre-reinforce wear-resistant surfaces or repair worn surfaces for mining, oil & gas, metallurgy, construction machinery, agricultural machinery, and steel industries.

Chemical Composition (Wt, %)

|

Grade |

Chemical Composi0on (Wt, %) |

|||||||

|

W |

T. C |

F. C |

Cr |

V |

Si |

O |

Fe |

|

|

ZTC11 |

95 – 96 |

3.8 – 4.1 |

≤ 0.08 |

≤ 0.01 |

≤ 0.05 |

≤ 0.02 |

≤ 0.05 |

≤ 0.3 |

OO

Grade and Particle Size

|

Grade |

Par(cle Size (mesh)* |

Corresponsive Size Range (μm) |

|

ZTC1109 |

– 20 + 30 |

– 850 + 600 |

|

ZTC1111 |

– 30 + 40 |

– 600 + 425 |

|

ZTC1115 |

– 40 + 60 |

– 425 + 250 |

|

ZTC1119 |

– 60 + 80 |

– 250 + 180 |

|

ZTC1126 |

– 60 + 325 |

– 250 + 45 |

|

ZTC1127 |

– 70 + 400 |

– 212 + 38 |

|

ZTC1123 |

– 80 + 120 |

– 180 + 125 |

|

ZTC1149 |

– 80 + 170 |

– 180 + 90 |

|

ZTC1128 |

– 80 + 200 |

– 180 + 75 |

|

ZTC1129 |

– 100 + 140 |

– 150 + 106 |

|

ZTC1130 |

– 100 + 200 |

– 150 + 75 |

|

ZTC1131 |

– 100 + 230 |

– 150 + 63 |

|

ZTC1133 |

– 100 + 325 |

– 150 + 45 |

|

ZTC1134 |

– 120 + 170 |

– 125 + 90 |

|

ZTC1190 |

– 120 + 230 |

– 125 + 63 |

|

ZTC1140 |

– 140 + 200 |

– 106 + 75 |

|

ZTC1139 |

– 140 + 325 |

– 106 + 45 |

|

ZTC1142 |

– 170 + 325 |

– 90 + 45 |

|

ZTC1143 |

– 200 + 325 |

– 75 + 45 |

|

ZTC1147 |

– 325 |

– 45 |

|

ZTC1148 |

– 400 |

– 38 |

*: We can tailor-make different par7cle sizes for various applications.

English

English Afrikaans

Afrikaans Albanian

Albanian Amharic

Amharic Arabic

Arabic Armenian

Armenian Basque

Basque Belarusian

Belarusian Bengali

Bengali Bosnian

Bosnian Bulgarian

Bulgarian Catalan

Catalan Cebuano

Cebuano Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch Esperanto

Esperanto Estonian

Estonian Finnish

Finnish French

French Frisian

Frisian Galician

Galician Georgian

Georgian German

German Greek

Greek Hebrew

Hebrew Hindi

Hindi Hungarian

Hungarian Indonesian

Indonesian Icelandic

Icelandic Italian

Italian Japanese

Japanese Javanese

Javanese Kannada

Kannada Kazakh

Kazakh Khmer

Khmer Korean

Korean Kurdish

Kurdish Kyrgyz

Kyrgyz Lao

Lao Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Malay

Malay Malayalam

Malayalam Marathi

Marathi Mongolian

Mongolian Myanmar

Myanmar Nepali

Nepali Norwegian

Norwegian Occitan

Occitan Panjabi

Panjabi Pashto

Pashto Persian

Persian Polish

Polish Portuguese

Portuguese Romanian

Romanian Russian

Russian Scottish Gaelic

Scottish Gaelic Serbian

Serbian Sindhi

Sindhi Sinhala

Sinhala Slovak

Slovak Slovenian

Slovenian Spanish (Mexico)

Spanish (Mexico) Spanish (Spain)

Spanish (Spain) Swahili

Swahili Swedish

Swedish Tagalog

Tagalog Tamil

Tamil Tatar

Tatar Telugu

Telugu Thai

Thai Turkish

Turkish Uighur

Uighur Ukrainian

Ukrainian Uzbek

Uzbek Urdu

Urdu Vietnamese

Vietnamese Welsh

Welsh