Pùdar spraeadh teirmeach WC-10Co4Cr

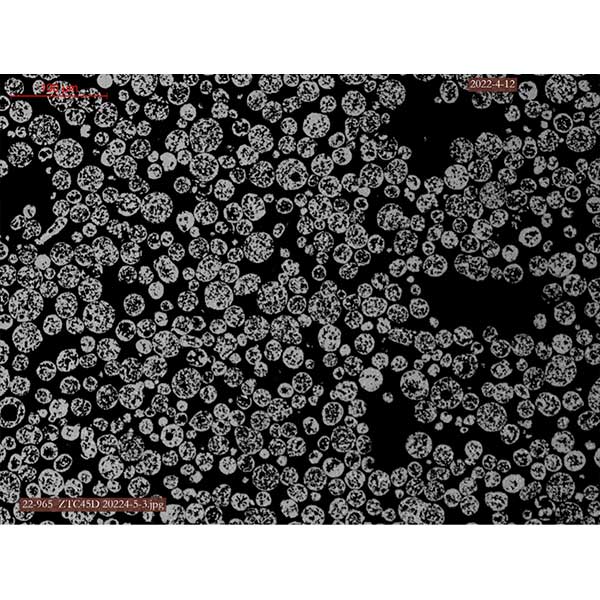

- Tha an dà phùdar Agglomerated & Sintered agus Sintered and Crushed rim faighinn. Tha pùdar cruinnichte agus sintered spherical no faisg air spherical le deagh shruth. Tha pùdar sintered agus pronnadh neo-riaghailteach.

- Tha an teòthachd seirbheis as àirde suas ri 500 ℃.

- Tha cruas àrd aig a’ chòmhdach tiugh le sàr-aghaidh an aghaidh caitheamh sgrìobach, caitheamh fretting, caitheamh adhesive, agus caitheamh bleith.

- A’ dol an àite plating chrome cruaidh.

- Tha an aghaidh creimeadh agus feartan caitheamh nas fheàrr aig Cobalt & Chrome na Cobalt, gu sònraichte ann an àrainneachdan fliuch is corrach.

- Air a chleachdadh sa mhòr-chuid ann an gèar laighe itealain, bhalbhaichean geata, bhalbhaichean ball, rolairean pàipeir, siolandairean uisgeachaidh, slatan teannachaidh, rolairean meatailteach, pàirtean meacanaigeach, msaa.

Ìre & cumadh ceimigeach

|

Ìre |

Co-dhèanamh ceimigeach (Wt, %) |

|||||

|

W |

T. C |

Co |

Cr |

Fe |

O |

|

|

ZTC45 |

Cothromachadh |

5.2 – 6.0 |

9.1 – 10.1 |

3.0 – 4.5 |

≤ 1.0 |

≤ 0.5 |

|

ZTC45D* |

Cothromachadh |

5.2 – 6.0 |

9.1 – 10.1 |

3.0 – 4.5 |

≤ 0.15 |

≤ 0.5 |

*: Tha D a’ seasamh airson pùdar spraeadh teirmeach spherical no faisg air spherical.

Sònrachadh & Feartan Corporra

|

Ìre |

Seòrsa |

Meud bloigh (μm) |

Dùmhlachd follaiseach (g/cm³) |

Ìre sruth (s/50g) |

Iarrtas |

|

ZTC4551 |

WC - Co - Cr 86/10/4 air a shineadh & air a phronnadh |

– 53 + 20 |

≥ 4 |

≤ 25 |

(JP5000 & JP8000, DJ2600 & DJ2700, JetKote, Jet Woka, K2)

|

|

ZTC4553 |

– 45 + 20 |

≥ 4 |

≤ 25 |

||

|

ZTC4552 |

– 45 + 15 |

≥4 |

≤ 25 |

||

|

ZTC4551D |

WC - Co - Cr 86/10/4 Agglomerated & Sìnte |

– 53 + 20 |

≥ 4 |

≤ 18 |

|

|

ZTC4553D |

– 45 + 20 |

≥ 4 |

≤18 |

||

|

ZTC4552D |

– 45 + 15 |

≥ 4 |

≤18 |

||

|

ZTC4581D |

– 45 + 11 |

≥ 4 |

≤18 |

||

|

ZTC4554D |

– 38 + 10 |

≥ 4 |

≤18 |

||

|

ZTC4582D |

– 30 + 10 |

≥ 4 |

≤ 18 |

||

| Is urrainn dhuinn diofar sgaoilidhean meud mìrean agus dùmhlachdan follaiseach a dhèanamh airson diofar thagraidhean. | |||||

| Paramadairean spraeraidh a thathar a’ moladh (HVOF) |

|

Feartan còmhdach |

||

| Stuth |

WC - 10Co - 4Cr |

|

cruas (HV0.3) |

1150 – 1400 |

| Dèanamh |

Agglomerated & sintered |

|

Neart ceangail (MPa) |

> 70MPa |

| Meud bloigh ( µ m) |

– 45 + 15 |

|

Èifeachdas air a thasgadh (%) |

40 – 55% |

| Spray Torch |

JP5000 |

|

Porosity (%) |

<1% |

| Nozzle (òirleach) |

6 |

|

|

|

| Ceirisean (L/h) |

24 |

|

||

| Ocsaidean (L/mion) |

944 |

|

||

| Gas giùlain (Ar) (L / min) |

7.5 |

|

||

| Ìre beathachaidh pùdar (g/mion) |

70 – 80 |

|

||

| Astar spraeraidh (mm) |

340 – 380 |

|

||

Gàidhlig na h-Alba

Gàidhlig na h-Alba Sasannach

Sasannach Afrikaanach

Afrikaanach Albànianach

Albànianach Amharic

Amharic Arabach

Arabach Armenianach

Armenianach Basgach

Basgach Belarusianach

Belarusianach Bengàlach

Bengàlach Bosnianach

Bosnianach Bulgàrianach

Bulgàrianach Catalanach

Catalanach Cebuano

Cebuano Croatianach

Croatianach Seacach

Seacach Dànach

Dànach Duitseach

Duitseach Esperanto

Esperanto Estòinianach

Estòinianach Fionnlaineach

Fionnlaineach Frangach

Frangach Frisianach

Frisianach Galicianach

Galicianach Georgianach

Georgianach Gearmailteach

Gearmailteach Grèigeach

Grèigeach Eabhrach

Eabhrach Indeach

Indeach Hungàrianach

Hungàrianach And-Innseach

And-Innseach Innis Tìleach

Innis Tìleach Eadailteach

Eadailteach Iapanach

Iapanach Iabhaininnseach

Iabhaininnseach Kannada

Kannada Kasakh

Kasakh Ciméireach

Ciméireach Corèanach

Corèanach Curdach

Curdach Kyrgyz

Kyrgyz Lao

Lao Latbhianach

Latbhianach Lithuanianach

Lithuanianach Macedonianach

Macedonianach Malaidheach

Malaidheach Malayalamach

Malayalamach Marathiach

Marathiach Mongolianach

Mongolianach Myanmar

Myanmar Nepalach

Nepalach Lochlannach

Lochlannach Occitan

Occitan Panjabi

Panjabi Pashto

Pashto Persianach

Persianach Pòlainneach

Pòlainneach Portugalach

Portugalach Romànianach

Romànianach Ruiseanach

Ruiseanach Serbianach

Serbianach Sindeach

Sindeach Sinhala

Sinhala Slovacanach

Slovacanach Slobhenianach

Slobhenianach Spàinntis (Mexico)

Spàinntis (Mexico) Spàinntis (An Spàinnt)

Spàinntis (An Spàinnt) Swahilieach

Swahilieach Suaineach

Suaineach Tagalogach

Tagalogach Tamileach

Tamileach Tatarais

Tatarais Telugach

Telugach Thaidheach

Thaidheach Turcach

Turcach Uighur

Uighur Ucràinis

Ucràinis Uzbek

Uzbek Urdu

Urdu Bhietnam

Bhietnam Cuimris

Cuimris