Cr3C2-37WC-18NiCoCr Pùdar spraeadh teirmeach

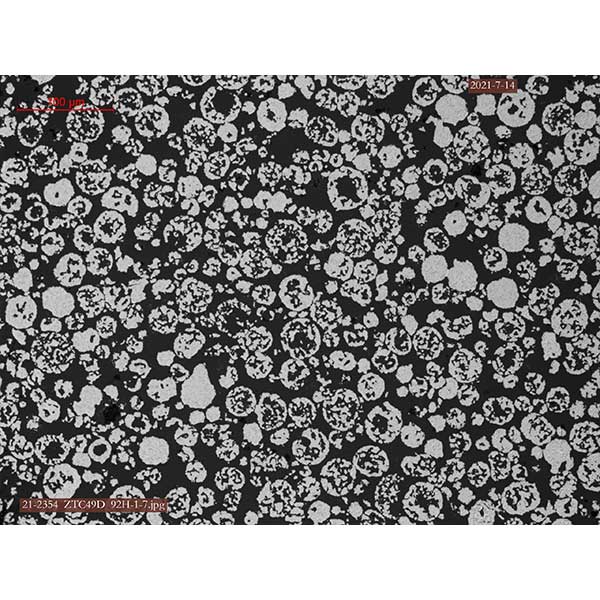

- Mìrean spherical no faisg air spherical agglomerated agus sintered liath-dubh.

- The maximum service temperature is up to 700℃.

- Tha an còmhdach sàr-mhath an aghaidh caitheamh sleamhnachaidh, caitheamh sgrìobach, caitheamh bleith, caitheamh creimneach, cavitation, agus creimeadh.

- Sàr-aghaidh an aghaidh creimeadh cruaidh, leaghan agus gas ann an teòthachd àrdaichte.

- Excellent resistance to high-temperature complex corrosion.

Mainly used in pump valve parts, power generation boilers, biomass-burning boilers, the chemical

Ìre & cumadh ceimigeach

|

Ìre |

Co-dhèanamh ceimigeach (Wt, %) |

||||||

|

W |

T. C |

Co |

Ni |

Cr |

O |

Fe |

|

|

ZTC49D* |

Cothromachadh |

7.8 – 8.4 |

3 – 4 |

10.5 – 12.5 | 39.5 – 42.5 |

≤ 0.5 |

< 0.5 |

*: Tha D a’ seasamh airson pùdar spraeadh teirmeach spherical no faisg air spherical.

Meud & Feartan Corporra

|

Ìre |

Seòrsa |

Meud bloigh (μm) |

Dùmhlachd follaiseach (g/cm³) |

Ìre sruth (s/50g) |

Iarrtas |

|

ZTC4951D |

Cr3c2 – WC – NiCoCr 45/37/18 Agglomerated & Sìnte |

– 53 + 20 |

≥ 2.5 |

— |

(JP5000 & JP8000, DJ2600 & DJ2700, JetKote, Jet Woka, K2)

|

|

ZTC4953D |

– 45 + 20 |

≥ 2.5 |

— |

||

|

ZTC4952D |

– 45 + 15 |

≥ 2.5 |

— |

||

|

ZTC4981D |

– 45 + 11 |

≥ 2.5 |

— |

||

|

ZTC4954D |

– 38 + 10 |

≥ 2.5 |

— |

||

|

ZTC4982D |

– 30 + 10 |

≥ 2.5 |

— |

||

| Is urrainn dhuinn diofar sgaoilidhean meud mìrean agus dùmhlachdan follaiseach a dhèanamh airson diofar thagraidhean. | |||||

| Paramadairean spraeraidh a thathar a’ moladh (HVOF) |

|

Feartan còmhdach |

||

| Stuth |

Cr3c2 – 37WC – 18NiCoCr |

|

cruas (HV0.3) |

1050 – 1250 |

| Dèanamh |

Agglomerated & sintered |

|

Neart ceangail (MPa) |

> 60MPa |

| Meud bloigh ( µ m) |

– 45 + 15 |

|

Èifeachdas air a thasgadh (%) |

40 – 48% |

| Spray Torch |

JP5000 |

|

Porosity (%) |

<3% |

| Nozzle (òirleach) |

6 |

|

|

|

| Ceirisean (L/h) |

25 |

|

||

| Ocsaidean (L/mion) |

900 |

|

||

| Gas giùlain (Ar) (L / min) |

7.5 |

|

||

| Ìre beathachaidh pùdar (g/mion) |

70 – 80 |

|

||

| Astar spraeraidh (mm) |

320 – 380 |

|

||

Gàidhlig na h-Alba

Gàidhlig na h-Alba Sasannach

Sasannach Afrikaanach

Afrikaanach Albànianach

Albànianach Amharic

Amharic Arabach

Arabach Armenianach

Armenianach Basgach

Basgach Belarusianach

Belarusianach Bengàlach

Bengàlach Bosnianach

Bosnianach Bulgàrianach

Bulgàrianach Catalanach

Catalanach Cebuano

Cebuano Croatianach

Croatianach Seacach

Seacach Dànach

Dànach Duitseach

Duitseach Esperanto

Esperanto Estòinianach

Estòinianach Fionnlaineach

Fionnlaineach Frangach

Frangach Frisianach

Frisianach Galicianach

Galicianach Georgianach

Georgianach Gearmailteach

Gearmailteach Grèigeach

Grèigeach Eabhrach

Eabhrach Indeach

Indeach Hungàrianach

Hungàrianach And-Innseach

And-Innseach Innis Tìleach

Innis Tìleach Eadailteach

Eadailteach Iapanach

Iapanach Iabhaininnseach

Iabhaininnseach Kannada

Kannada Kasakh

Kasakh Ciméireach

Ciméireach Corèanach

Corèanach Curdach

Curdach Kyrgyz

Kyrgyz Lao

Lao Latbhianach

Latbhianach Lithuanianach

Lithuanianach Macedonianach

Macedonianach Malaidheach

Malaidheach Malayalamach

Malayalamach Marathiach

Marathiach Mongolianach

Mongolianach Myanmar

Myanmar Nepalach

Nepalach Lochlannach

Lochlannach Occitan

Occitan Panjabi

Panjabi Pashto

Pashto Persianach

Persianach Pòlainneach

Pòlainneach Portugalach

Portugalach Romànianach

Romànianach Ruiseanach

Ruiseanach Serbianach

Serbianach Sindeach

Sindeach Sinhala

Sinhala Slovacanach

Slovacanach Slobhenianach

Slobhenianach Spàinntis (Mexico)

Spàinntis (Mexico) Spàinntis (An Spàinnt)

Spàinntis (An Spàinnt) Swahilieach

Swahilieach Suaineach

Suaineach Tagalogach

Tagalogach Tamileach

Tamileach Tatarais

Tatarais Telugach

Telugach Thaidheach

Thaidheach Turcach

Turcach Uighur

Uighur Ucràinis

Ucràinis Uzbek

Uzbek Urdu

Urdu Bhietnam

Bhietnam Cuimris

Cuimris