Paletten aus Hartmetall

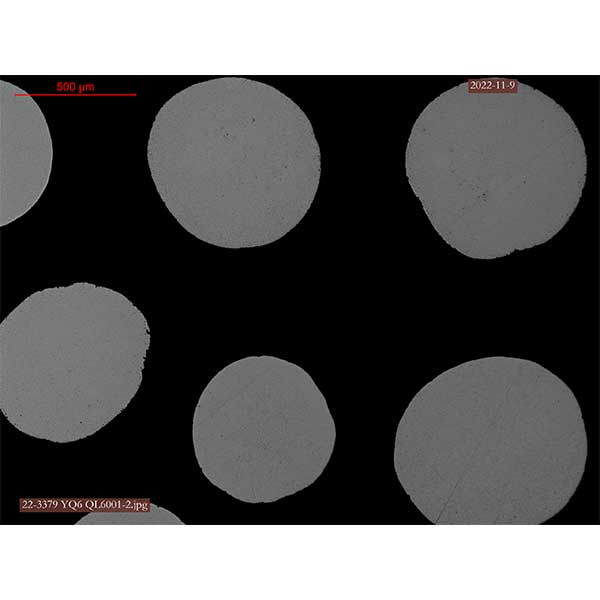

Cemented Carbide Pellet (CCP) is made of WC and Co through granulating, pressing, and sintering and is spherical or subspherical dark gray cemented carbide particles with high hardness (1400-1600 HV0.1), high wear resistance, and erosion resistance.

CCP is used to prepare cemented carbide wear-resistant electrodes (wire), spray welding materials, and surfacing materials. The primary purpose is to pre-reinforce wear-resistant surfaces or repair worn surfaces for mining, oil & gas, metallurgy, construction machinery, agricultural machinery, and steel industries.

Chemische Zusammensetzung (Gew., %)

|

Klasse |

Chemical Composi(on (wt, %) |

|||||

|

Co |

T. C |

F. C |

Ti |

Fe |

O |

|

|

ZTC31 |

6.5-7.2 |

5.4-5.8 |

≤0.01 |

≤0.5 |

≤0.5 |

≤0.8 |

|

ZTC32 |

3.5-4.0 |

5.5-5.9 |

≤0.01 |

≤0.5 |

≤0.5 |

≤0.8 |

|

ZTC33 |

5.7-6.3 |

5.4-5.8 |

≤0.01 |

≤0.5 |

≤0.5 |

≤0.3 |

Körnung und Partikelgröße

|

Klasse |

Physical Properties |

Microstructure |

|||

|

Density (g/cm3) |

Hardness (HV) |

Porosity (≤) |

Free Carbon (≤) |

Microstructure |

|

|

ZTC31 |

14.5-15.0 |

≥1400 |

A04B04 |

C04 |

No decarburization and no Cobalt aggregation. |

|

ZTC32 |

14.8-15.3 |

≥1500 |

A04B04 |

C04 |

|

|

ZTC33 |

14.5-15.0 |

≥1400 |

A04B04 |

C02 |

|

Deutsch

Deutsch Englisch

Englisch Afrikaans

Afrikaans albanisch

albanisch Birmanisch

Birmanisch Arabisch

Arabisch Armenisch

Armenisch baskisch

baskisch Belarussisch

Belarussisch Bengali

Bengali bosnisch

bosnisch bulgarisch

bulgarisch katalanisch

katalanisch Cebuano

Cebuano kroatisch

kroatisch Tschechisch

Tschechisch dänisch

dänisch Niederländisch

Niederländisch Esperanto

Esperanto estnisch

estnisch finnisch

finnisch Französisch

Französisch Friesisch

Friesisch galizisch

galizisch georgisch

georgisch griechisch

griechisch hebräisch

hebräisch Hindi

Hindi ungarisch

ungarisch Indonesisch

Indonesisch isländisch

isländisch Italienisch

Italienisch japanisch

japanisch Javanisch

Javanisch Nepalesisch

Nepalesisch Kasachisch

Kasachisch Khmer

Khmer Koreanisch

Koreanisch kurdisch

kurdisch Kirgisisch

Kirgisisch Lao

Lao lettisch

lettisch litauisch

litauisch mazedonisch

mazedonisch malaiisch

malaiisch Lettisch

Lettisch Marathi

Marathi mongolisch

mongolisch Myanmar

Myanmar Nepalesisch

Nepalesisch norwegisch

norwegisch Okzitanisch

Okzitanisch Panjabi

Panjabi Persisch

Persisch persisch

persisch Polieren

Polieren Portugiesisch

Portugiesisch rumänisch

rumänisch Russisch

Russisch schottisch Gälisch

schottisch Gälisch serbisch

serbisch Singhalesisch

Singhalesisch Singhalesisch

Singhalesisch slowakisch

slowakisch Slowenisch

Slowenisch Spanisch (Mexiko)

Spanisch (Mexiko) Spanisch (Spanien)

Spanisch (Spanien) Suaheli

Suaheli Schwedisch

Schwedisch Tagalog

Tagalog Tamil

Tamil Tatarisch

Tatarisch Telugu

Telugu Thai

Thai Türkisch

Türkisch Uigurisch

Uigurisch ukrainisch

ukrainisch Usbekisch

Usbekisch Urdu

Urdu Vietnamesisch

Vietnamesisch Walisisch

Walisisch