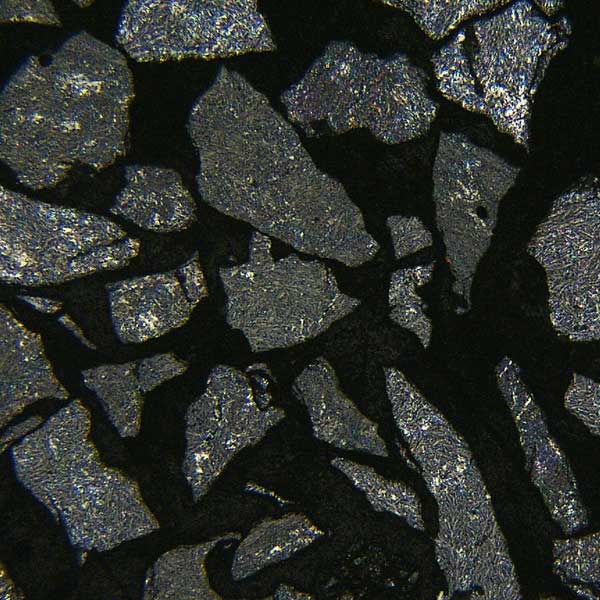

Powdwr Carbid Twngsten Cast

Mae Powdwr Cast Twngsten Carbide (CTC) wedi'i wneud o doddi a malu W a WC ac mae'n ronynnau llwyd tywyll afreolaidd gyda phwynt toddi uchel (2525 ℃), caledwch uchel (≥ 2000 HV0.1), a gwrthiant gwisgo rhagorol.

Defnyddir CTC i baratoi powdr darnau matrics PDC, powdwr Plasma Arc Welding (PTAW), deunyddiau weldio chwistrellu, electrodau gwrthsefyll traul carbid sment (gwifren), ac ati Y prif bwrpas yw rhag-atgyfnerthu arwynebau sy'n gwrthsefyll traul neu atgyweirio arwynebau sydd wedi treulio. ar gyfer mwyngloddio, olew a nwy, meteleg, peiriannau adeiladu, peiriannau amaethyddol, a diwydiannau dur.

Cyfansoddiad Cemegol (Wt, %)

|

Gradd |

Cyfansoddion Cemegol (Wt, %) |

|||||||

|

W |

T. C |

F. C |

Cr |

V |

Si |

O |

Fe |

|

|

ZTC11 |

95 – 96 |

3.8 – 4.1 |

≤ 0.08 |

≤ 0.01 |

≤ 0.05 |

≤ 0.02 |

≤ 0.05 |

≤ 0.3 |

OO

Gradd a Maint Gronyn

|

Gradd |

Par(cle Maint (rhwyll)* |

Amrediad Maint Cyfatebol (μm) |

|

ZTC1109 |

– 20 + 30 |

– 850 + 600 |

|

ZTC1111 |

– 30 + 40 |

– 600 + 425 |

|

ZTC1115 |

– 40 + 60 |

– 425 + 250 |

|

ZTC1119 |

– 60 + 80 |

– 250 + 180 |

|

ZTC1126 |

– 60 + 325 |

– 250 + 45 |

|

ZTC1127 |

– 70 + 400 |

– 212 + 38 |

|

ZTC1123 |

– 80 + 120 |

– 180 + 125 |

|

ZTC1149 |

– 80 + 170 |

– 180 + 90 |

|

ZTC1128 |

– 80 + 200 |

– 180 + 75 |

|

ZTC1129 |

– 100 + 140 |

– 150 + 106 |

|

ZTC1130 |

– 100 + 200 |

– 150 + 75 |

|

ZTC1131 |

– 100 + 230 |

– 150 + 63 |

|

ZTC1133 |

– 100 + 325 |

– 150 + 45 |

|

ZTC1134 |

– 120 + 170 |

– 125 + 90 |

|

ZTC1190 |

– 120 + 230 |

– 125 + 63 |

|

ZTC1140 |

– 140 + 200 |

– 106 + 75 |

|

ZTC1139 |

– 140 + 325 |

– 106 + 45 |

|

ZTC1142 |

– 170 + 325 |

– 90 + 45 |

|

ZTC1143 |

– 200 + 325 |

– 75 + 45 |

|

ZTC1147 |

– 325 |

– 45 |

|

ZTC1148 |

– 400 |

– 38 |

*: Gallwn deilwra-gwneud meintiau par7cle gwahanol ar gyfer ceisiadau amrywiol.

Cymraeg

Cymraeg Saesneg

Saesneg Affricaneg

Affricaneg Albaneg

Albaneg Amhareg

Amhareg Arabeg

Arabeg Armenaidd

Armenaidd Basgeg

Basgeg Belarwseg

Belarwseg Bengali

Bengali Bosnieg

Bosnieg Bwlgareg

Bwlgareg Catalaneg

Catalaneg Cebuano

Cebuano Croateg

Croateg Tsiec

Tsiec Daneg

Daneg Iseldireg

Iseldireg Esperanto

Esperanto Estoneg

Estoneg Ffinneg

Ffinneg Ffrangeg

Ffrangeg Ffriseg

Ffriseg Galiseg

Galiseg Sioraidd

Sioraidd Almaeneg

Almaeneg Groeg

Groeg Hebraeg

Hebraeg Hindi

Hindi Hwngareg

Hwngareg Indoneseg

Indoneseg Islandeg

Islandeg Eidaleg

Eidaleg Japaneaidd

Japaneaidd Jafaneg

Jafaneg Kannada

Kannada Kazakh

Kazakh Khmer

Khmer Corëeg

Corëeg Cwrdaidd

Cwrdaidd Kyrgyz

Kyrgyz Lao

Lao Latfieg

Latfieg Lithwaneg

Lithwaneg Macedonaidd

Macedonaidd Maleieg

Maleieg Malayalam

Malayalam Marathi

Marathi Mongoleg

Mongoleg Myanmar

Myanmar Nepali

Nepali Norwyaidd

Norwyaidd Ocsitaneg

Ocsitaneg Panjabi

Panjabi Pashto

Pashto Perseg

Perseg Pwyleg

Pwyleg Portiwgaleg

Portiwgaleg Rwmania

Rwmania Rwsiaidd

Rwsiaidd Gaeleg yr Alban

Gaeleg yr Alban Serbeg

Serbeg Sindhi

Sindhi Sinhala

Sinhala Slofaceg

Slofaceg Slofeneg

Slofeneg Sbaeneg (Mecsico)

Sbaeneg (Mecsico) Sbaeneg (Sbaen)

Sbaeneg (Sbaen) Swahili

Swahili Swedeg

Swedeg Tagalog

Tagalog Tamil

Tamil Tatar

Tatar Telugu

Telugu Thai

Thai Twrceg

Twrceg Uighur

Uighur Wcrain

Wcrain Wsbeceg

Wsbeceg Wrdw

Wrdw Fietnameg

Fietnameg