ZTC72 Series Matrix powders ለPDC ቢት

The ZTC72 series matrix powder is designed explicitly for PDC bits. It has superior erosion resistance, abrasion resistance, and good infiltration performance.

ኬሚካላዊ ቅንብር (Wt፣ %)

|

ደረጃ |

ሲእሱሚካል ቅንብር (Wt፣ %) |

||||||||

|

ወ |

ፌ |

ቲ.ሲ |

ኤፍ.ሲ |

Mo |

ናይ |

ቲ |

ታ |

Nb |

|

|

ZTC7232K1 |

ሚዛን |

≤ 3.2 |

5.2 – 5.6 |

≤ 0.04 |

≤ 0.1 |

— |

≤ 0.08 |

≤ 0.03 |

≤ 0.03 |

|

ZTC7232K2 |

ሚዛን |

2.5 – 3.0 |

5.7 – 6.0 |

≤ 0.04 |

≤ 0.05 |

— |

≤ 0.03 |

≤ 0.03 |

≤ 0.03 |

|

ZTC7232K3 |

ሚዛን |

≤ 1.0 |

5.4 – 5.9 |

≤ 0.04 |

≤ 0.1 |

1.5 – 2.5 |

≤ 0.08 |

≤ 0.03 |

≤ 0.03 |

ደረጃ እና ቅንጣት መጠን

|

ደረጃ |

የንጥል መጠን (ሜሽ)* |

Apparent Density (g/cm3) |

Tap Density (g/cm3) |

ተሻጋሪ ስብራት ጥንካሬ (ኤምፓ) |

Hardness (HRC) |

|

ZTC7232K1 |

– 80 + 325 |

7.3 – 8.5 |

9.5 – 10.0 |

586 – 862 |

34 – 42 |

|

ZTC7232K2 |

– 80 + 325 |

7.2 – 8.2 |

10.5 – 10.9 |

655 – 1000 |

38 – 42 |

|

ZTC7232K3 |

– 60 + 325 |

7.2 – 8.2 |

9.1 – 9.8 |

620 – 931 |

32 – 40 |

*: ለተለያዩ አፕሊኬሽኖች የተለያዩ የቅንጣት መጠኖችን ማበጀት እንችላለን ።

Characteristics and Application

|

ደረጃ |

Characteristic |

መተግበሪያ |

|

ZTC7232K1 |

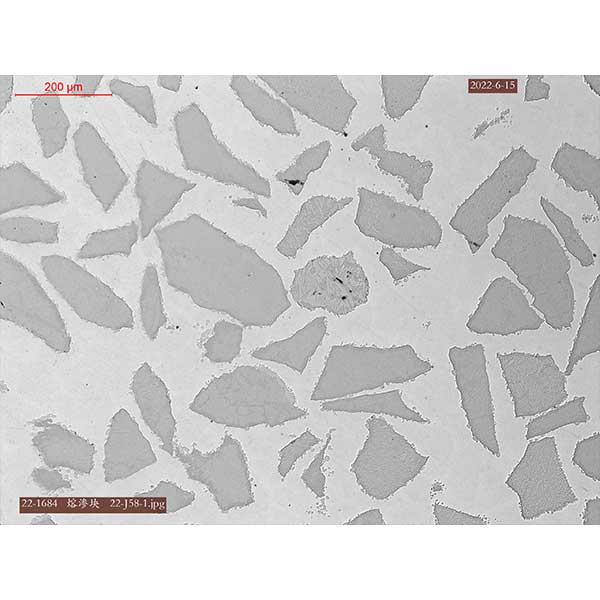

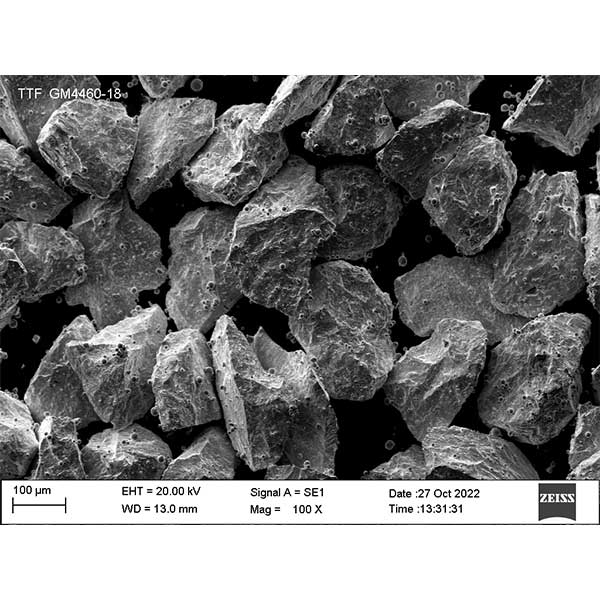

This grade mainly consists of cast tungsten carbide and macrocrystalline tungsten carbide, a popular grade in most PDC bits plants. By controlling particle size, the powder has a higher apparent density and tap density, which shows superior wear and erosion resistance than other tungsten carbide matrix powders. | Mainly used in erosion-resistant, wear-resistant, and impact-resistant infiltration drill products. |

|

ZTC7232K2 |

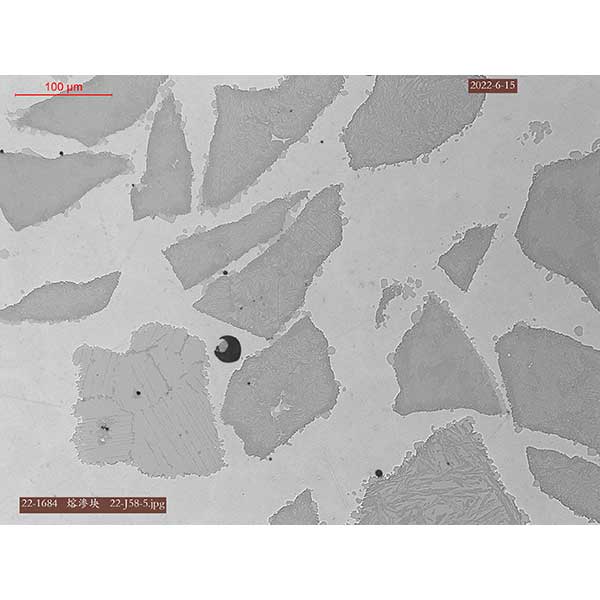

This grade mainly consists of cast tungsten carbide and macrocrystalline tungsten carbide. The optimized particle size distribution gives the product excellent wear resistance after infiltration. | Mainly used in harsh working conditions that are easy to wear and erosion. |

|

ZTC7232K3 |

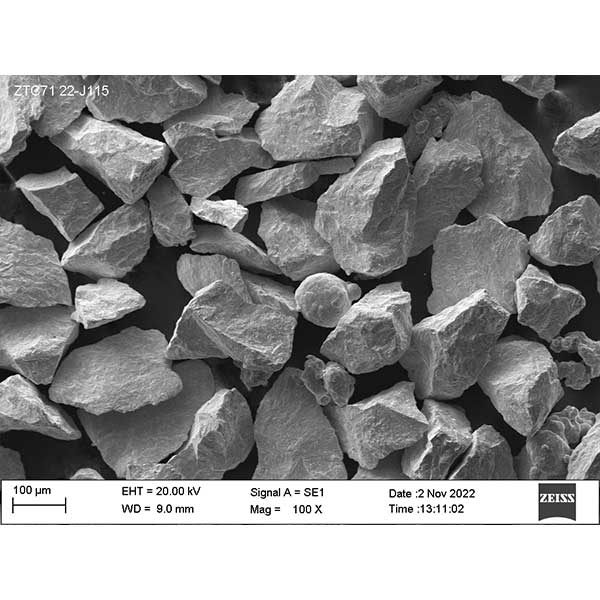

This grade mainly consists of cast tungsten carbide, macrocrystalline tungsten carbide, and nickel powder. By controlling particle size, the powder has a higher apparent density and tap density, which shows combined wear, erosion, and impact resistance. | Mainly used in erosion-resistant, wear-resistant, and impact-resistant infiltration drill products. |

አማርኛ

አማርኛ እንግሊዝኛ

እንግሊዝኛ አፍሪካንስ

አፍሪካንስ አልበንያኛ

አልበንያኛ አረብኛ

አረብኛ አርመንያኛ

አርመንያኛ ባስክ

ባስክ ቤላሩሲያን

ቤላሩሲያን ቤንጋሊ

ቤንጋሊ ቦስንያን

ቦስንያን ቡልጋርያኛ

ቡልጋርያኛ ካታሊያን

ካታሊያን ሴቡአኖ

ሴቡአኖ ክሮኤሽያን

ክሮኤሽያን ቼክ

ቼክ ዳኒሽ

ዳኒሽ ደች

ደች እስፔራንቶ

እስፔራንቶ ኢስቶኒያን

ኢስቶኒያን ፊኒሽ

ፊኒሽ ፈረንሳይኛ

ፈረንሳይኛ ፍሪሲያን

ፍሪሲያን ጋላሺያን

ጋላሺያን ጆርጅያን

ጆርጅያን ጀርመንኛ

ጀርመንኛ ግሪክኛ

ግሪክኛ ሂብሩ

ሂብሩ ሂንዲ

ሂንዲ ሃንጋሪያን

ሃንጋሪያን ኢንዶኔዥያን

ኢንዶኔዥያን አይስላንዲ ክ

አይስላንዲ ክ ጣሊያንኛ

ጣሊያንኛ ጃፓንኛ

ጃፓንኛ ጃቫኒስ

ጃቫኒስ ካናዳ

ካናዳ ካዛክሀ

ካዛክሀ ክመር

ክመር ኮሪያኛ

ኮሪያኛ ኩርዲሽ

ኩርዲሽ ክይርግያዝ

ክይርግያዝ ላኦ

ላኦ ላትቪያን

ላትቪያን ሊቱኒያን

ሊቱኒያን ማስዶንያን

ማስዶንያን ማላይ

ማላይ ማላያላም

ማላያላም ማራቲ

ማራቲ ሞኒጎሊያን

ሞኒጎሊያን ማይንማር

ማይንማር ኔፓሊ

ኔፓሊ ኖርወይኛ

ኖርወይኛ ኦሲታን

ኦሲታን ፓንጃቢ

ፓንጃቢ ፓሽቶ

ፓሽቶ ፐርሽያን

ፐርሽያን ፖሊሽ

ፖሊሽ ፖርቹጋልኛ

ፖርቹጋልኛ ሮማንያን

ሮማንያን ራሺያኛ

ራሺያኛ ስኮትላንዳዊ ጌሊክ

ስኮትላንዳዊ ጌሊክ ሰሪቢያን

ሰሪቢያን ስንድሂ

ስንድሂ ሲንሃላ

ሲንሃላ ስሎቫክ

ስሎቫክ ስሎቬንያን

ስሎቬንያን ስፓኒሽ (ሜክሲኮ)

ስፓኒሽ (ሜክሲኮ) ስፓኒሽ (ስፔን)

ስፓኒሽ (ስፔን) ስዋሕሊ

ስዋሕሊ ስዊድንኛ

ስዊድንኛ ታንጋሎግ

ታንጋሎግ ታሚል

ታሚል ታታር

ታታር ተሉጉ

ተሉጉ ታይ

ታይ ቱሪክሽ

ቱሪክሽ ኡጉር

ኡጉር ዩክሬንያን

ዩክሬንያን ኡዝቤክ

ኡዝቤክ ኡርዱ

ኡርዱ ቪትናሜሴ

ቪትናሜሴ ዋልሽ

ዋልሽ